Inertia friction welding features different sized flywheels that are attached to the chuck and spindle shaft. A motor is connected to the spindle shaft to rotate the part. At the start of the welding cycle, the motor is connected to the spindle shaft and rotates the part to the desired rotational speed. Once the desired speed is achieved, the motor is disconnected from the spindle shaft. Based on the weight of the part, spindle shaft, chuck, and flywheels, a rotational inertia is created by the free spinning components. At this point the frictional welded process as described above takes place, utilizing the rotational inertia to create frictional heat when the parts are brought together. Learn why you should combine inertia welding with CNC machining.

Product brief

Inertia friction welding features different sized flywheels that are attached to the chuck and spindle shaft. A motor is connected to the spindle shaft to rotate the part. At the start of the welding cycle, the motor is connected to the spindle shaft and rotates the part to the desired rotational speed. Once the desired speed is achieved, the motor is disconnected from the spindle shaft. Based on the weight of the part, spindle shaft, chuck, and flywheels, a rotational inertia is created by the free spinning components. At this point the frictional welded process as described above takes place, utilizing the rotational inertia to create frictional heat when the parts are brought together. Learn why you should combine inertia welding with CNC machining.

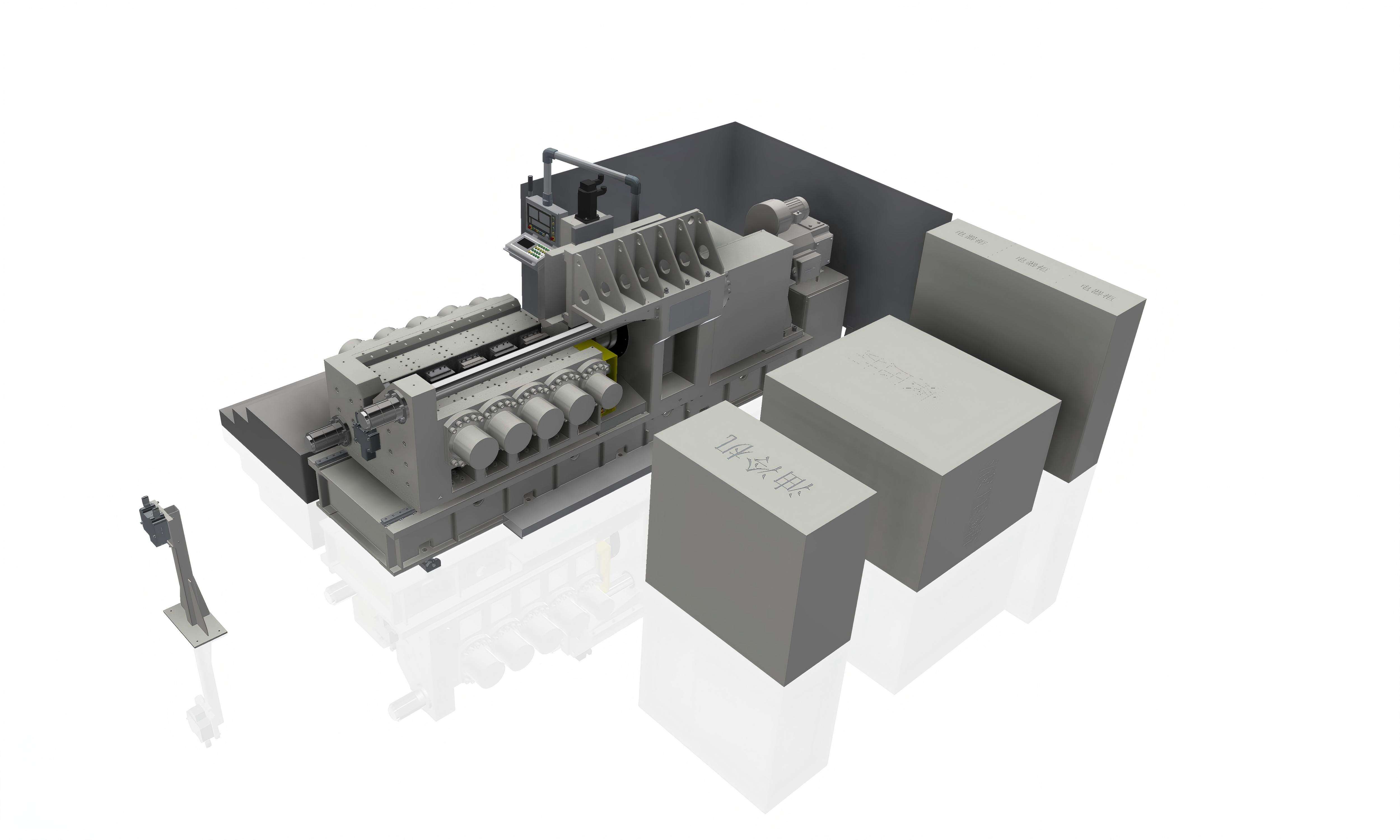

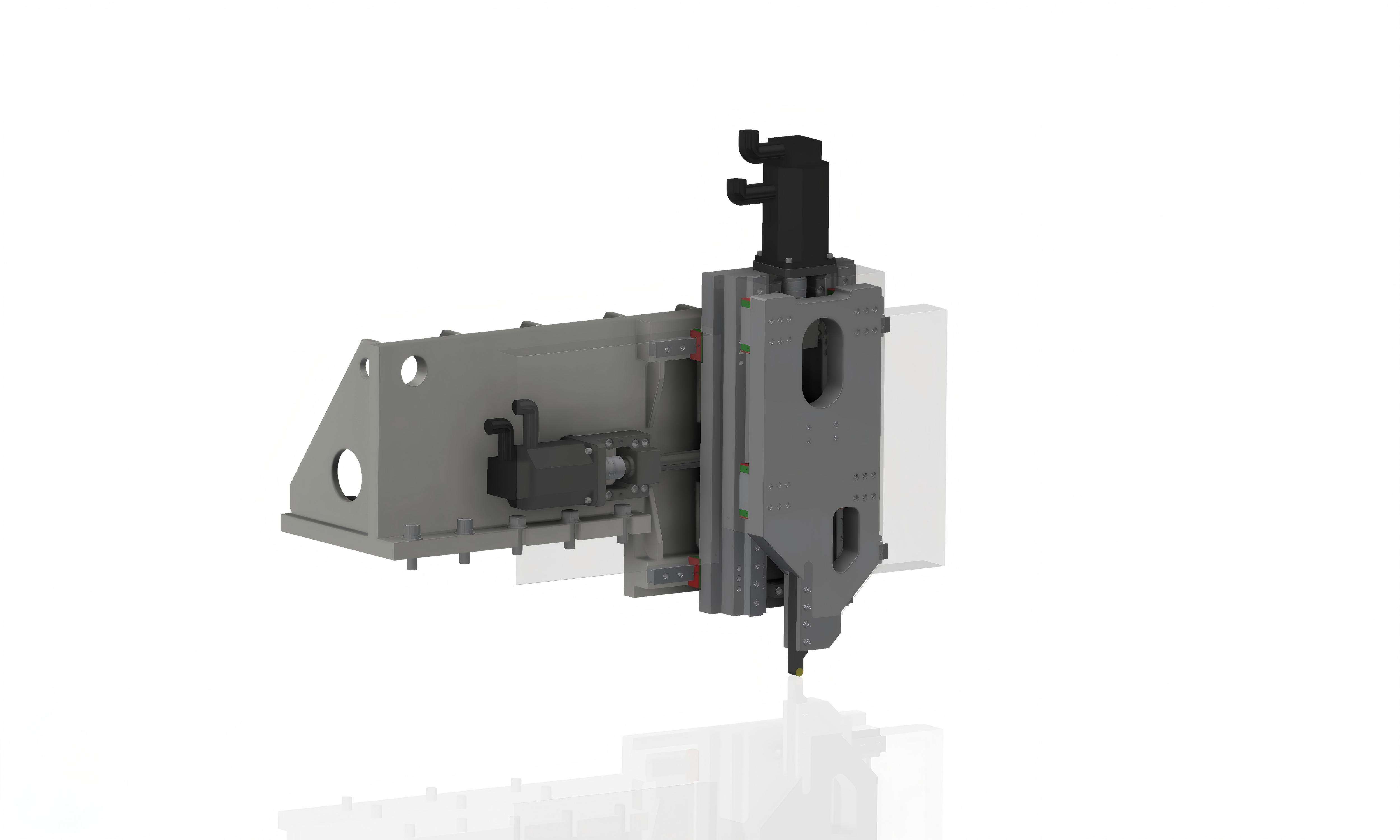

Product Description

Product parameters

| Model | Max.upset force(KN) | Max.welding area(mm) | Welding dia. | Speed(rpm) |

| DBS-2 | 20 | 20-140 | 5-13 | 5000 |

| DBS-5 | 50 | 50-260 | 8-18 | 3000 |

| DBS-12 | 120 | 150-700 | 14-30 | 1500 |

| DBS-20 | 200 | 150-1020 | 14-36 | 1500 |

| DBS-30 | 300 | 314-1600 | 20-45 | 1200 |

| DBS-40 | 400 | 500-2400 | 25-55 | 1100 |

| DBS-63 | 630 | 960-3400 | 35-64 | 1000 |

| DBS-80 | 800 | 1300-5000 | 40-75 | 950 |

| DBS-100 | 1000 | 1600-6000 | 45-86 | 890 |

| DBS-125 | 1250 | 2000-7800 | 50-100 | 600 |

| DBS-160 | 1600 | 4300-8792 | 89-160 | 580 |

| DBS-200 | 2000 | 5100-12500 | 102-189 | 500 |

| DBS-250 | 2500 | 3850-15500 | 70-140 | 500 |

| DBS-320 | 3200 | 6400-20000 | 90-160 | 380 |

| DBS-400 | 4000 | 8000-25000 | 100-180 | 350 |

| DBS-500 | 5000 | 8000-31400 | 100-200 | 320 |

| DBS-700 | 7000 | 8000-44000 | 100-240 | 320 |