What to Look For When Buying ER Collet Sets:

Product brief

Product brief

What to Look For When Buying ER Collet Sets:

Product Description

ER collets are widely used in machining and manufacturing for holding cutting tools or workpieces with high precision, especially in CNC milling and turning operations, offering versatility and reliability in various applications. Here's a breakdown of their applications:

Product parameters

| Size | Range |

| ER8-9PCS | 1+0.5mm(1,1.5,2,2.5,3,3.5,4,4.5mm) |

| ER8-5PCS | 1/16-3/16(1/16,3/32,1/8,5/32,3/16) |

| ER11-7PCS | 1-7mm(1,2,3,4,5,6,7mm) |

| ER11-13PCS | 1+0.5-7mm(1,1.5,2,2.5,3,3.5,4,4.5,5,5.5,6,6.5,7mm) |

| ER11-7PCS | 1/16-1/4(1/16,3/32,1/8,5/32,3/16,7/32,1/4) |

| ER16-10PCS | 1-10mm(1,2,3,4,5,6,7,8,9,10mm) |

| ER16-8PCS | 3-10mm(3,4,5,6,7,8,9,10mm) |

| ER16-10PCS | 1/32-3/8(1/32,1/16,3/32,1/8,3/16,7/32,1/4,5/16,11/32,3/8) |

| ER20-12PCS | 2-13mm(2,3,4,5,6,7,8,9,10,11,12,13mm) |

| ER20-12PCS | 1/16-1/2(1/16,3/32,1/8,3/16,7/32,1/4,5/16,11/32,3/8,13/32,7/16,1/2) |

| ER25-15PCS | 2-16mm(2,3,4,5,6,7,8,910,11,12,13,14,15,16mm) |

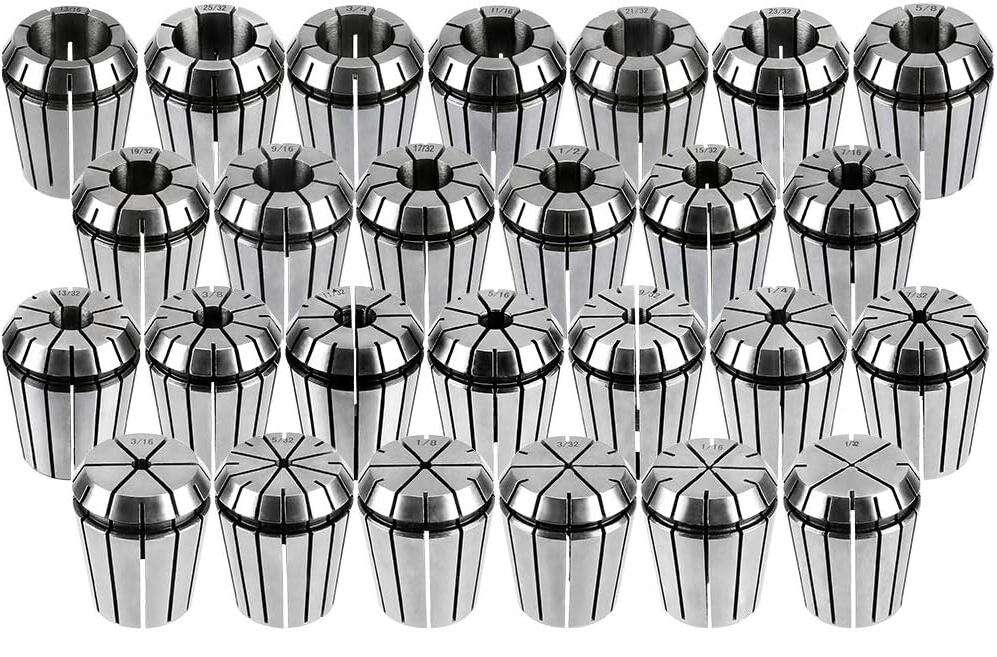

| ER25-15PCS | 1/16-5/8(1/16,3/32,1/8,3/16,7/32,1/4,5/16,11/32,3/8,13/32,7/16,1/2,17/32,9/16,5/8) |

| ER32-18PCS | 3-20mm(3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20mm) |

| ER32-18PCS | 1/16-25/32(1/16,3/32,1/8,3/16,7/32,1/4,5/16,11/32,3/8,13/32,7/16,1/2,17/32, 9/16,5/8 ,21/32,11/16,3/4,25/32) |

| ER40-23PCS | 4-26mm(4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26mm) |

| ER40-23PCS | 1/16-1(1/16,3/32,1/8,3/16,7/32,1/4,5/16,11/32,3/8,13/32,7/16,1/2,17/32,9/16, 5/8 ,21/32,11/16,3/4,25/32,13/16,27/32,7/8,15/16,31/32,1) |